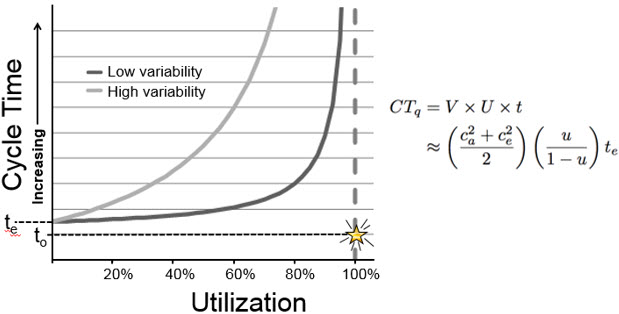

Employee capacity planning directly affects employee morale and performance. Many companies do capacity planning and staffing using a “seat of the pants” approach and their productivity suffers. Unfortunately, the relationship between employee utilization and work variability is not well understood. Managers want people busy all the time because busy people are viewed as productive people. This is actually an unproductive approach. Capacity planning for any resource must take into account utilization AND variability.

To learn new concepts you can use now, join us for a two day Lean Physics for Managers seminar in Chicago on June 5th and 6th. Click here for more info and to register. No PhD required. It’s practical operations science any manager will be able to apply as soon as they return to the office.

It’s a law of nature, you will never schedule your people at 100% utilization over the long term. See “The Overtime Vicious Cycle” in Factory Physics, Spearman and Hopp, 3rd Edition (Waveland Press: LongGrove, IL) p.316. Many managers do not understand the basic relationship between cycle time, variability and utilization. Following is a compilation of responses when participants at an industry conference were asked to draw the relationship between cycle time and utilization:

The red line indicates the correct response and a few knew it but this is a fundamental relationship that is not widely understood. For a manager not to know this intuitively would be like a homeowner not knowing the relationship between mortgage interest rates and the monthly mortgage payment. The correct relationship, and the equation that models the behavior, is here:

The red line indicates the correct response and a few knew it but this is a fundamental relationship that is not widely understood. For a manager not to know this intuitively would be like a homeowner not knowing the relationship between mortgage interest rates and the monthly mortgage payment. The correct relationship, and the equation that models the behavior, is here:

For more information on the science behind this relationship, see Factory Physics for Managers, pp 72 – 80. For discussion of this relationship as it relates to common accounting practices and associated problems, click here.

So are you pushing your employees too hard? If you are unaware of what their utilization is, who knows? That’s a kind of Russian roulette management approach. If you know your employees’ capacity and are scheduling them at 100% of their capacity, you are definitely pushing them too hard. If there is more variability in your processes, you should schedule at lower levels of utilization. Note on the second graph that the cycle time at ~40% utilization on the high variability curve can be achieved at ~90% utilization on the low variability curve. Much more work can be completed for a given response time when there is less variability. Variability shows up as inconsistent work content or quality (process variability) or in poorly scheduled sequencing of tasks (flow variability).

For specifics on calculating capacity utilization, see the Capacity Analysis section in Factory Physics for Managers starting on page 138.

A practical approach that leverages the scientific relationship described above is to:

This approach works in both classic manufacturing operations and in service operations such as project management, product development, and hospital emergency departments. In Lean-Driven Innovation, Norbert Majerus, (2016, CRC Press: New York), p. 239, Mr. Majerus describes a classic capacity planning struggle in scheduling product design iterations (the unit of work involving engineering resources) for product development, “Jean-Pierre pleaded with his business leaders, ‘We scheduled 120 iterations last month and we delivered 40 on time. Please let me schedule 80 iterations next month and we will deliver 70 when you need them–a gain of 30 iterations!’ The arguments did not work, but after a year they agreed to try it, and Jean-Pierre’s team delivered what he promised, which finally convinced them.”

Certainly there are “soft” skills such as leadership, communication, and team-building required to motivate employees’ performance. However, ignoring the hard facts of the relationships between cycle time, utilization and variability can destroy employee performance no matter how good your soft skills are.

ESP